1000Kn karfe na duniya na gwaji na duniya

- Bayanin samfurin

Eldro-hydraulic tro / microcomper na gwaji na duniya gwaji

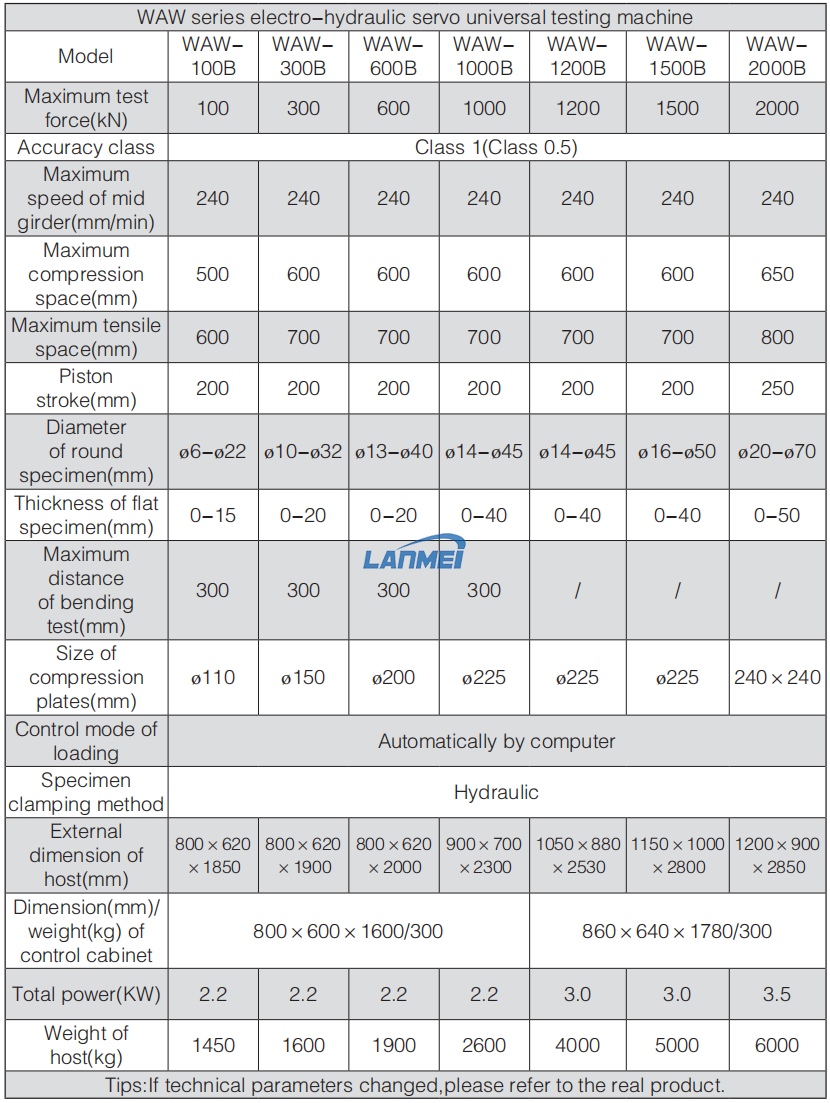

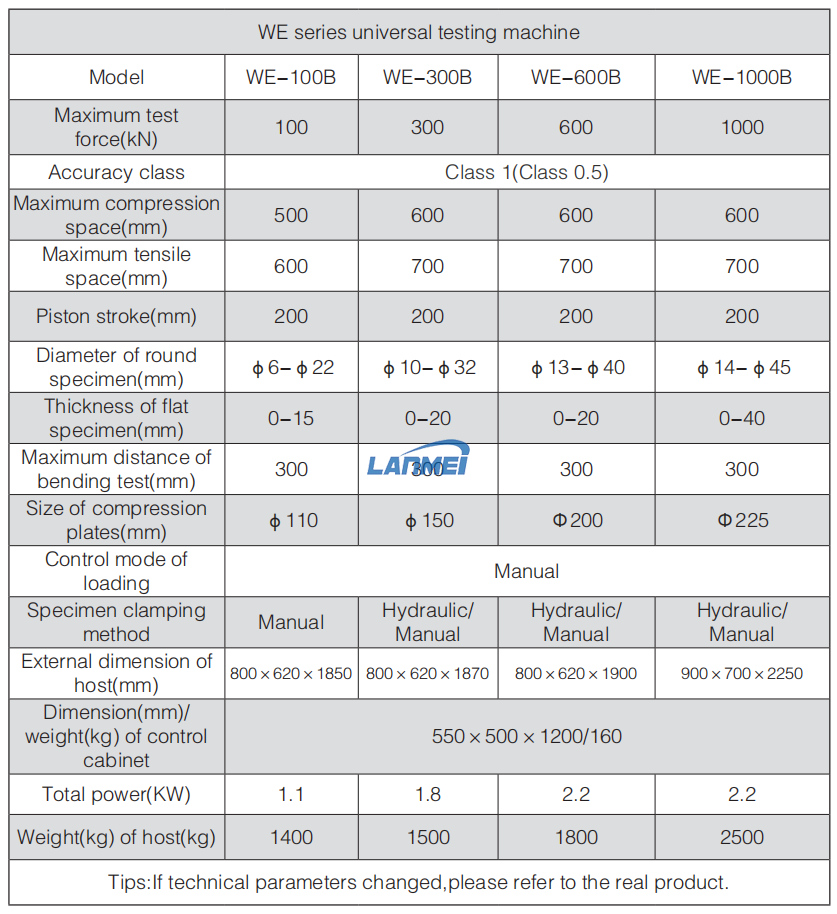

Waw jerin elecro-hydraulic Sermin daftarin da ke GB / T16826-2008 "FILG10" Masana Elevely ALMINCEMENCE wanda An inganta da masana'antu dangane da wannan. Wannan jerin gwanon sarrafawa yana ɗoki da kayan aikin da ba shi da ƙarfi, yana gwada abubuwa da yawa, suna gwada abubuwa da yawa. Ya cika GB, Iso, Astm, Din, JIS da sauran ka'idodi.

Abubuwan fasali na jerin abubuwan da aka tsara WAW Seriel-Serto Universal Ma'anar da (nau'in b):

1.The gwajin da aka samo microcomputer atomatik Yanayin atomatik, tare da ayyukan ci gaba na ci gaba, ƙuduri, mai kulawa da ƙarfi da iri na kulawa;

2.Dopt babban-daidaitaccen HUB-da-magana don auna karfi;

3.host wanda ke ɗaukar shafi huɗu-shafi huɗu da kuma tsarin sikirin gwaji

4.comware tare da PC ta hanyar sadarwa mai amfani da Ethernet;

5.Mage gwajin gwaji ta hanyar daidaitawa;

6. Uightwararrun ƙarfin, babban ƙarfi da kyawawan kariyar yanar gizo don kariya ta aminci.

Farkon aiki da kwamishinan

Bayan an gama shigarwa na lantarki, kunna kan karfin kayan aiki, kunna kayan aikin sarrafawa, to, ku tsayar da abin da ke cikin sarrafawa, to, ku kiyaye idanuwancin sarrafawa), don ku cika tasirin aikin koli), to, ku kiyaye idanuwancin sarrafawa), idan an sami kayan aikin soja, idan Yau, ya kamata ka cirewa kuma ka tsaya don bincika, magance matsala; Idan ba haka ba, zazzage har sai piston ƙasa zuwa matsayin al'ada, kwamishi ya ƙare.

5. Wada hanya

Hanyar aiki na gwajin rebar

1.switch akan iko, tabbatar cewa maɓallin dakatarwar gaggawa yana pop-up, kunna mai sarrafawa a kan kwamitin.

2.Akraording zuwa abun cikin gwajin rubutu da buƙatun, zaɓi da kuma sanya matsa mai dacewa. Girman girman Clam ya zaɓi girman ƙirar. Ya kamata a lura cewa shigarwa na matsa ya kamata

Ka yi daidai da nuni a matsa.

3.Turn a kwamfutar, Shiga software "Mai Gwaji" kuma shigar da sigogin gwajin gwargwadon tsarin gwajin (amfani da hanyar sarrafawa ana nuna shi a cikin "Jagorar Mayar da Garanti")

4.Pen da shinge, latsa "Jaw Loossen" button a kan Control Panels da kuma daidaita saman muƙafi, da farko yakan bayyana rufe saman mu muƙamuƙi.

5. Kunna shinge, ya kula da darajar gudun hijira, fara aikin gwaji (amfani da hanyar sarrafawa ana nuna shi a cikin tsarin kayan sarrafawa ".

Bayan gwajin, ana yin rikodin bayanan ta atomatik a cikin tsarin sarrafawa, kuma saita abun ciki na tsarin sarrafawa don Bugawa na Data don Bugawa ta Data (Hanyar saiti na firinta na firinta ")

7.removences mai mahimmanci gwargwadon gwajin gwajin, rufe allon isarwa (waw production model) ko latsa samfurori na "dakatarwa".

8.Quit software, rufe famfo, rufe da kuma babban iko, goge da kuma tsaftace saura kan aiki, dunƙule da kuma kawar da shafar wuraren watsa kayan aiki.

6.ly lura

Yarjejeniyar Kulawa

1.each lokaci kafin fara injin don Allah duba idan akwai zubar da mai (takamaiman sassa), bututun mai), ko wutan lantarki), ko wutar lantarki ne; Duba kullun, kula da amincin abubuwan da aka gyara.

2.Daga kowane gwajin piston ya kamata a jefa zuwa mafi ƙasƙanci matsayi, da kuma saukewa a cikin lokaci, inda za a iya tsayawa a cikin lokaci, inda za a iya yuwu don maganin rigakafi.

3. Workeration bayan wani lokaci, ya kamata ka sami mai zama dole bincike da kuma kiyayewa tare da injin gwaji: tsaftace ragowar da karfe kuma tsatsa a saman zamewa da kuma grirster. Duba tsananin sarkar kowane rabin shekara; Greased da subing sassan sassan a kai a kai, fenti sassa da sauki tare da kanti tsatsa mai, kasance tsaftacewa da anti-tsatsa.

4.Amma daga zazzabi mai girma, ma rigar, ƙura, matsakaiciyar matsakaici, kayan aikin lalata ruwa.

5.repaukar mai na shukar jiki a shekara ko tarawa bayan sa'o'i 2000.

6.Da shigar da wasu software a kwamfutar, domin gujewa yin software na sarrafa tsarin gudanarwa na gwaji. hana kwamfutar daga kamuwa da ƙwayar cuta.

7. Don fara injin da za ku bincika ko maɓallin haɗin kai tsakanin kwamfutar da mai masaukin hannu da kuma loosening, zaka iya boot bayan tabbatar da daidai.

Masiha m 8.an lokaci baza ku iya sanya murfin wutar lantarki da layin sigina ba, in ba haka ba yana da sauƙin lalata asalin sarrafawa.

9.Da gwajin, don Allah kar a danna maballin kwamitin sarrafawa ba da izini ba, akwatin aiki da software na gwaji.do ba zai tashi ba yayin gwajin. Kada ka sanya hannunka a cikin sararin gwaji yayin gwajin.

10.Daukar gwajin, kada ka taɓa kayan aiki da kowane nau'in hanyoyin haɗin yanar gizo, don kada su shafi daidaiton bayanan.

11.Ifen Duba matakin canjin tanki na tanki mai.

12.Check ko layin da aka haɗa da mai sarrafawa yana cikin kyakkyawar lamba a kai a kai, idan ya kasance sako-sako, ya kamata a daidaita da lokaci.

Bayan gwajin idan ba a yi amfani da kayan aikin na dogon lokaci ba, don Allah rufe kan babban ikon sarrafa kayan aiki da kuma nuna kayan aikin da aka yi amfani da shi akai-akai.

Shawara ta Musamman:

1.Zaya kayan aiki ne na kayan aiki, ya kamata mutane a cikin ajiyayyun matsayi don injin. An hana mutane horo don sarrafa mayar da injin.Ka zama mai ba da izini ko aiki na gwaji, don Allah nan da nan maɓallin TARIHI NA GASKIYA DA ZAI YI KYAUTA.

2.Fasten kwaya a kan type dunƙule na tanƙwara da tanƙwara kafin gwajin lanƙwasa, in ba haka ba zai lalata matsa lamba.

3. Saboda haka gwajin mai shimfiɗa, ka tabbatar da cewa babu wani abu a cikin sararin samaniya. Haramun ne ya jagoranci gwajin shimfidawa tare da na'urar lankwasa, in ba haka ba zai haifar da mummunar lalacewar kayan aiki ko hatsarin rauni na mutum

4.HAI DINAI GASKIYA DAGA CIKIN SAUKI KADA KA YI KYAUTA KYAUTA KYAUTA DA KYAUTATAWA, In ba haka ba zai haifar da mummunar lalacewa ga kayan aiki ko hatsarin rauni.

5.Wana kayan aikin suna buƙatar motsawa ko rushewar bututun ƙarfe da kewaya mai iyaka, don haka za'a iya sake haɗa shi da kyau; Lokacin da kayan aikin ke buƙatar hoisting, da fatan za a iya ɗaukar mayafin ƙasa zuwa mafi ƙasƙanci ko kuma ku zama mai ɗaukar hoto a cikin silinda, yana haifar da amfani da shi.